A low number of defective parts per million (PPM) is a fundamental indicator of a company’s product quality and production processes. A low PPM value has a positive impact on SIVA’s operations and, consequently and directly, on our customers.

Containment of internal costs

One of the main advantages of having a low PPM value is the containment and control of production costs. When a stamped part has defects, this generally results in scrap with a loss of materials and labor or rework with the consequent cost of labor and possibly equipment. This translates into competitiveness.

Reduction of non-quality costs for our customers

A defective stamped part can cause a machine and/or production line to stop, especially in the case of automation, resulting in high costs due to downtime, increased risks of non-compliance, and delays in delivery. This effectively represents a cost for the user of stamped parts. Quality is a choice; poor quality is not normal.

Hidden defects, not detectable during the production process, can lead to malfunctions of the final product, claims, and potentially even safety risks.

Increased customer satisfaction

A low PPM value can only improve the satisfaction of SIVA’s customers and their own customers. Production quality leads to a chain of healthy satisfaction, efficiency, and quality that reverberates throughout the production chain all the way to the end customer.

Increased reputation of SIVA’s customer

A company with low PPM levels easily gains a good reputation in the market. Customers, suppliers, and other stakeholders see companies that produce high-quality products as reliable and respectable. This can lead to greater confidence in the company and a higher likelihood of being chosen as a business partner.

Improvement of productivity

A low PPM value is the result of a stable and controlled process. The absence of interruptions due to the onset of defects allows more time for product and process improvement. A virtuous process stimulates growth and strengthens the quality attitude of the people involved.

In summary, a low PPM value of defective parts offers numerous and concrete advantages for a company, including a reduction in production costs, an increase in customer satisfaction and company reputation, an improvement in productivity, and a reduction in complaints.

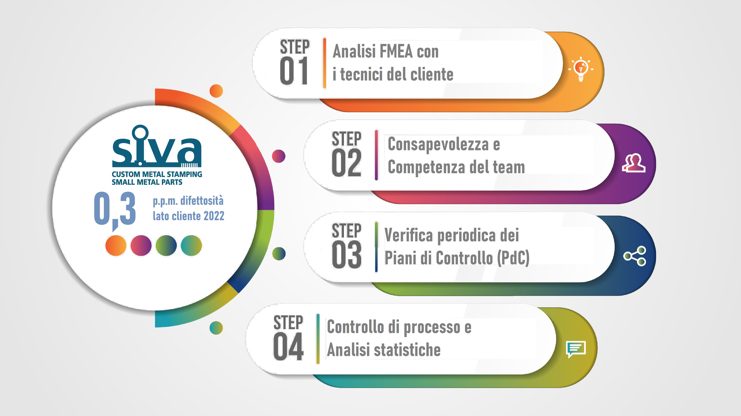

In 2022, we achieved a record threshold of 0.3 PPM of defective parts on customer’s side, and we continue to strive to maintain this positive trend of improvement throughout 2023!