Quality

Quality, proactivity, reliability, customer service, technical and organisational expertise, flexibility, teamwork and transparency are at the core of our corporate philosophy.

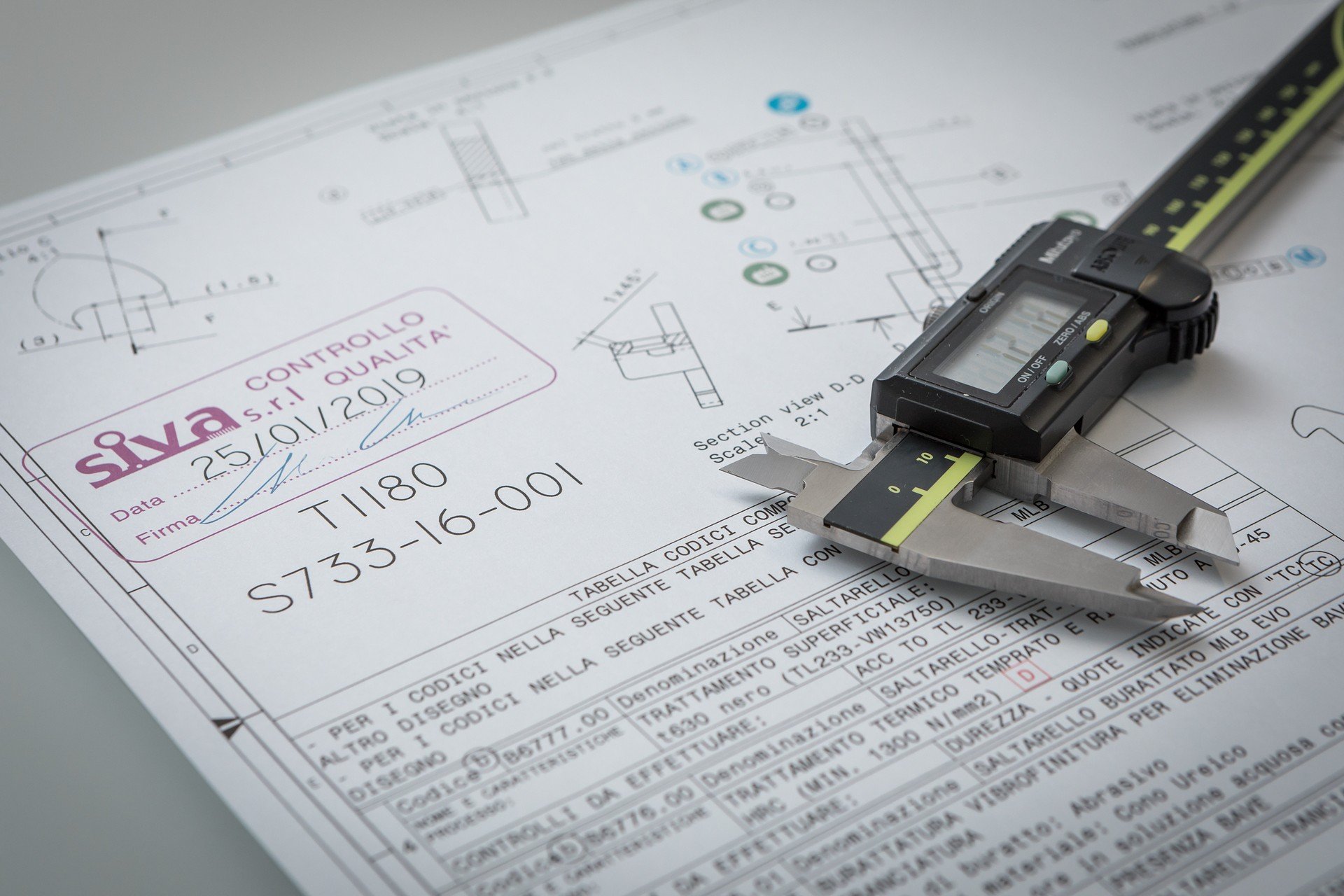

For us, Quality means value added for our customers, awareness, proactiveness, the pursuit of constant improvement all-round; it means streamlining and optimising all corporate processes, eliminating waste, identifying and eliminating inefficiencies and activities devoid of any added value. This is why we use latest-generation optical control machinery in our production departments, and why we apply Lean Production techniques (5S method).

We go well beyond the level of quality certified by UNI EN ISO 9001, attending also Safety and Environmental aspects, with a management system that entails the involvement and sharing of responsibilities across all levels. Quality and Safety mean Reliability for our customers, who can rely on a company that is there for its clientèle every step of the way, making on-time deliveries and focusing on doing long-term business.

The relationship based on trust which we have with our customers stems from our choice of total Transparency. We have developed sophisticated software algorithms in-house, allowing us to prepare accurate quotes and pricing, and we are open to discussions with customers to negotiate individual cost items for our stampings, to achieve mutual satisfaction on a regular basis.

Featured Items

Completed the creation of measurement programs in the optical measuring system for all of our products

One year has passed since the introduction of the optical measuring system in the Stamping department, and our technicians have succesfully completed the creation and development of the measuring programs, initially made for the highest rotation items. The new measuring system is located in

Revision of the Control Plans at customers’ premises

As part of the continuous improvement of its Quality System, SIVA is implementing the revision of the Control Plans of the parts in production through a more careful assessment of the Risks (Risk Analysis). SIVA has started a program of visits at customers’ premises

Five Years of 5S

The 5S arrived in SIVA in October 2008 after Lorenzo Antonelli came back from a study trip in Japan. At Yamada Ltd of Osaka he learned about the 5S directly from Mr. Yamada and his staff, who our entire company expresses its thanks and